Inventory Automation

Use Cases, Steps, Costs, ROI

ScienceSoft applies 12 years of experience in building supply chain management software and 13 years in IoT services to design and develop effective automated inventory solutions.

Inventory Automation: The Essence

Inventory automation facilitates monitoring of inventory levels and location, inventory valuation and audit, inventory ordering and selling. Automated inventory systems rely on IoT and AI technologies to provide end-to-end inventory automation. The solutions support multi-location inventory management, demand-driven inventory planning, and inventory optimization based on advanced analytics, which helps companies avoid stockouts and overstocking.

Inventory automation is especially helpful for large enterprises that need to manage a wide range of inventory items across complex multi-echelon distribution networks.

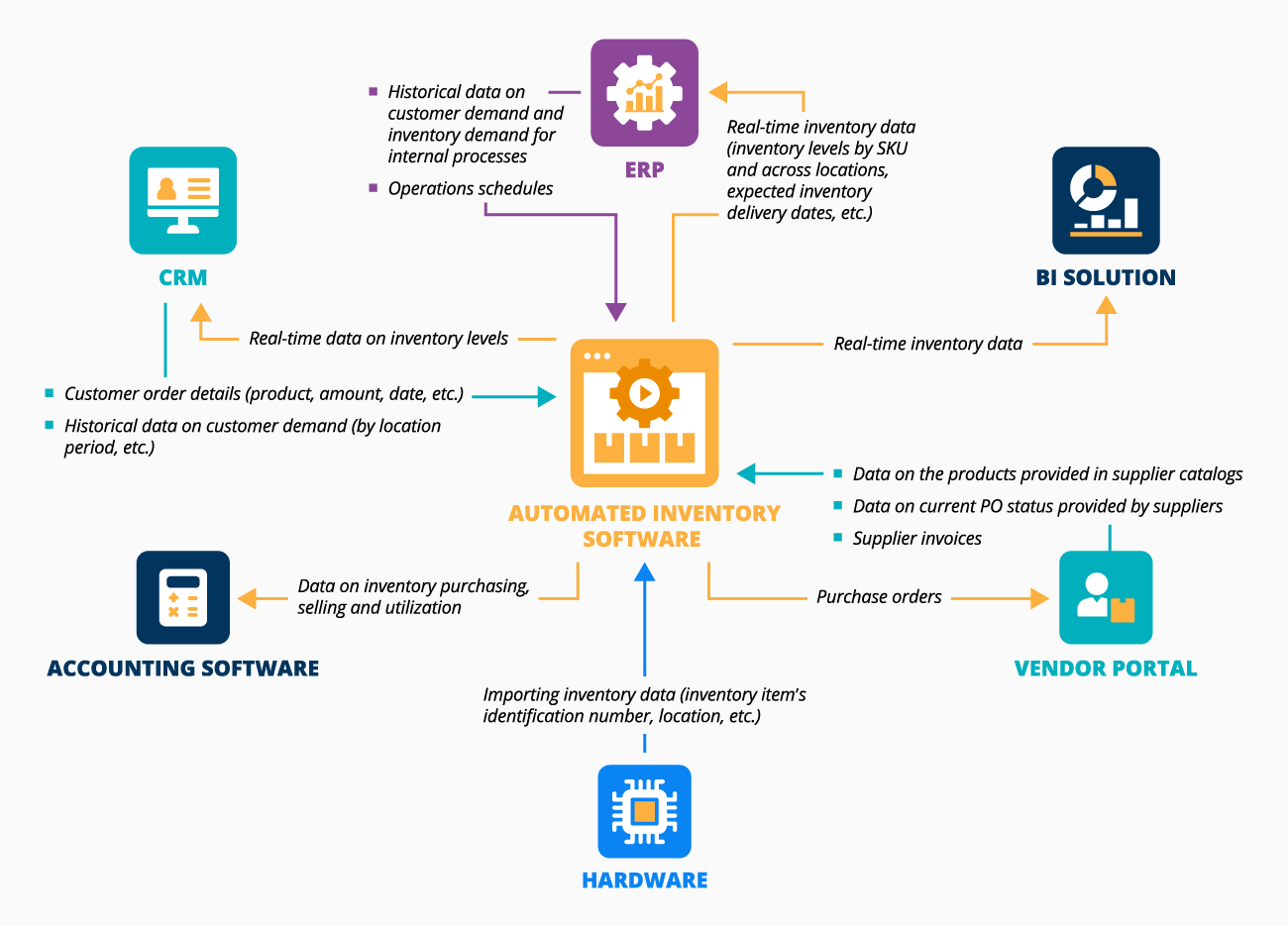

- Necessary integrations: ERP, CRM, accounting software, a vendor portal, etc.

- Implementation time: 8–12+ months.

- Development costs: $90,000–$400,000, depending on the automation solution's complexity. Use our free calculator to understand the cost for your case.

- ROI: up to 300%. Calculate ROI for your tailored solution.

Main Use Cases of Inventory Automation

Inventory planning

Achieve up to 30% reduction in an overall inventory amount due to analytics-based inventory planning and multi-echelon inventory optimization.

Inventory replenishment

Get intelligent guidance on when and how much inventory to purchase. Up to 99% of your inventory purchase orders can be managed automatically.

Inventory control

Employ RFID technology and the cutting-edge computer vision techs to drive up to 15x faster inventory counting and get 100% visibility of the real-time inventory levels across your storage locations.

Inventory distribution

With automated and optimized inventory operations, you’ll be able to increase the fill rate and spur the revenue growth. Also, you benefit from enhanced customer satisfaction due to timely order delivery.

Inventory Automation System: Key Features

Based on ScienceSoft’s experience in inventory software projects, we have summarized features that form the core of the automated inventory solution.

Essential Integrations for the Automated Inventory System

ScienceSoft recommends integrating the inventory automation system with relevant corporate solutions to bring end-to-end automation across inventory management processes.

Inventory automation system + ERP

- For accurate multi-location inventory planning.

- To plan optimal time for inventory reallocation from warehouses to the locations where operations are conducted.

- To leverage inventory data at all levels of operational and strategic planning.

Inventory automation system + CRM

Alternatively to CRM, the solution can be integrated directly with selling channels (e.g., a company’s ecommerce website or a point-of-sale (POS) system).

- For the automated input of relevant data when creating sales orders and customer invoices.

- For accurate omnichannel inventory planning to meet customer demand.

- To keep sales agents up-to-date on available inventory.

Inventory automation system + vendor portal

- For the automated input of product data when generating POs.

- For the automated PO submission to suppliers via a vendor portal.

- For facilitated PO status tracking.

- For faster processing of supplier invoices uploaded from a vendor portal.

Inventory automation system + accounting software

For automated recording of inventory transactions in the general ledger, accurate inventory value recording and reporting.

Inventory automation system + hardware

(barcode or RFID readers)

For accurate inventory level and location monitoring.

Inventory automation system + BI solution

For the analytics and visualization of multi-location inventory demand analytics, inventory lead time analytics, ABC and FSN analytics, and more.

Success Factors for Inventory Automation

In inventory automation projects, ScienceSoft always seeks to cover the following important factors that may bring the customer additional value across inventory management processes:

The use of barcode and RFID technology

To eliminate error-prone manual inventory counting, enable precise automated tracking of inventory level and location.

AI-powered prescriptive analytics

To provide inventory specialists with intelligent recommendations, for example, on optimal inventory reorder points or inventory reallocation time to support optimal inventory levels across various storage locations and manufacturing facilities.

A mobile app

with barcode scanning and QR code scanning capabilities. To enable employees who deal with physical inventory to track inventory levels and share inventory data with colleagues using their smartphones.

Proper user training

To help employees involved in inventory management quickly learn how to use software and integrated hardware (RFID or barcode scanners) to streamline their daily tasks.

Inventory Automation: Success Stories by ScienceSoft

23 results for:

How to Automate Inventory Workflows

Below, ScienceSoft shares a sample roadmap to inventory automation:

1

Business needs analysis and eliciting requirements for inventory automation.

2

Designing the functionality, architecture, and tech stack for the automated inventory system.

3

Project planning: deliverables, scope of work, duration, budget, team composition, etc.

4

Custom inventory automation software development OR upgrading a legacy inventory solution.

5

Running the necessary quality assurance procedures.

6

Inventory data migration (from spreadsheets or a previously used inventory management tool).

7

Software integration with the required systems, including hardware systems.

8

User training.

9

Continuous support and evolution of the automated inventory solution (optional).

Inventory Automation Techs and Tools ScienceSoft Uses

Inventory Automation Costs and Financial Outcomes

The cost of implementing inventory automation varies greatly depending on:

- The number and complexity of an automation solution’s functional modules.

- The amount of automation required for inventory tracking (semi-automation provided by barcode scanners or full automation enabled by RFID technology).

- The volume and complexity of data to be migrated from spreadsheets and/or existing inventory management software.

- The number and complexity of integrations (with ERP, CRM, accounting software, a vendor portal, a BI tool, etc.).

From ScienceSoft's experience, custom inventory automation software of average complexity may cost around $90,000–$250,000.

The cost of a comprehensive automated inventory control system for a large enterprise may reach $400,000+.

Want to know the cost of your inventory solution?

Benefits of inventory automation

Inventory automation can bring up to 300% ROI.

When to Opt for a Custom Inventory Automation System

ScienceSoft recommends building a custom automated inventory management system in the following cases:

|

|

You need to automate complex or specific inventory-related processes, such as the control of perishable or highly regulated (e.g., medicines, military equipment) inventory items that even customizable software products can’t handle efficiently. |

|

|

You need a flexible inventory automation solution that is easy to evolve, e.g., with advanced technologies like comprehensive AI-powered inventory analytics or RFID-enabled inventory monitoring. |

|

|

You are building a blockchain-based SCM system and need to enable facilitated inventory order traceability, inventory shipment tracking and inventory authenticity verification at each level of the supply chain. |

|

|

You want to avoid costly and complicated integration of inventory management automation software with your legacy corporate systems (ERP, CRM, accounting software, BI software, etc.). |

I recommend our clients with non-specific inventory processes and minimal requirements for the solution’s UX and UI consider platform-based development. From my experience, building an inventory automation system based on a low-code platform (e.g., Microsoft Power Apps) can bring up to 74% development cost savings.

Inventory Automation with ScienceSoft

In supply chain management software development since 2012, ScienceSoft helps companies build reliable inventory automation solutions. Our approach to development rests on the closest attention to quality, business value, and compliance with the intended cost and timelines.

Consulting services

- Analysis of your inventory automation needs.

- Suggesting optimal inventory automation features (including barcode- or RFID-enabled functionality), solution architecture, and tech stack.

- Preparing an integration plan with ERP, CRM, accounting software, RFID or barcode scanners, etc.

- Implementation cost & time estimates, expected ROI calculation.

Implementation services

- Inventory automation needs analysis.

- Automated inventory solution conceptualization.

- Architecture design.

- Inventory automation system development.

- Integrating the solution with the required corporate systems and hardware.

- Quality assurance.

- User training.

- Continuous support and evolution (if required).

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. Since 2012, we help organizations automate their inventory processes. Being ISO 9001 and ISO 27001 certified, we apply a mature quality management system and guarantee that cooperation with us does not pose any risks to our customers’ data security. If you are interested in getting a robust inventory automation system, feel free to turn to ScienceSoft’s team.