Custom Digital Inventory System: Overview

ScienceSoft applies 35 years of experience in custom software development for the manufacturing industry to help companies implement powerful digital inventory systems that simplify their unique 3D printing workflows.

The Essence of Digital Inventory System

A digital inventory system is used by companies engaged in additive manufacturing (AM) to store and validate 3D models, specifications, and production requirements for digital inventory items. The system simplifies the process of 3D print ordering and helps ensure consistent quality of prints via:

- Production information accompanying each digital inventory item and shared across geographically dispersed manufacturing facilities.

- Re-ordering of successful prints.

A custom digital inventory system is commonly used in AM for 3D printing of complex tooling and spare parts and rapid prototyping to test the efficiency of product designs.

Custom digital inventory software development may require $100,000–$350,000+ in investments, depending on the solution complexity. You are welcome to use our free calculator to estimate the cost for your case.

Key Features of Digital Inventory System

Relying on ScienceSoft’s experience in inventory software projects, we have summarized features that form the core of the digital inventory system.

Digital inventory data storage

- Storage of multiple file formats for 3D models and supporting production documentation, e.g., materials, technologies, post-processing procedures for digital inventory items (.pdf, .doc, .xls, etc.).

- Version control.

Digital inventory items management

- Manual/automated uploading of 3D models + their specifications and recommended production requirements (materials, technologies, post-processing procedures, etc.).

- 3D model viewer.

- Automated validation of digital inventory items for printing (checking critical parameters: a model’s density, walls thickness, orientation, etc.).

- Integrated team collaboration tools (e.g., to work on 3D models, their specifications and production requirements).

- Cataloging of digital inventory items with a powerful search engine (filtering and metadata querying).

- CAD file conversion to STL (for 3D printing).

3D print orders management and reporting

*This feature set requires integration with ERP and other business workflow systems, e.g., manufacturing execution system (MES).

- 3D print order placement, with the selection of the required materials, post-processing procedures (e.g., heat treatment, machine finishing, dyeing), and a QA program (required part quality checks).

- 3D print order routing (to internal or external production).

- 3D printing cost and time estimation (based on production requirements).

- 3D print order status tracking and updates.

- 3D print orders history and re-ordering.

- Production analytics reporting (successful vs. failed prints, throughput, costs, etc.).

Data access & security

- User permission configuration.

- User activity logs.

- Encrypted storage and transfer of digital inventory data.

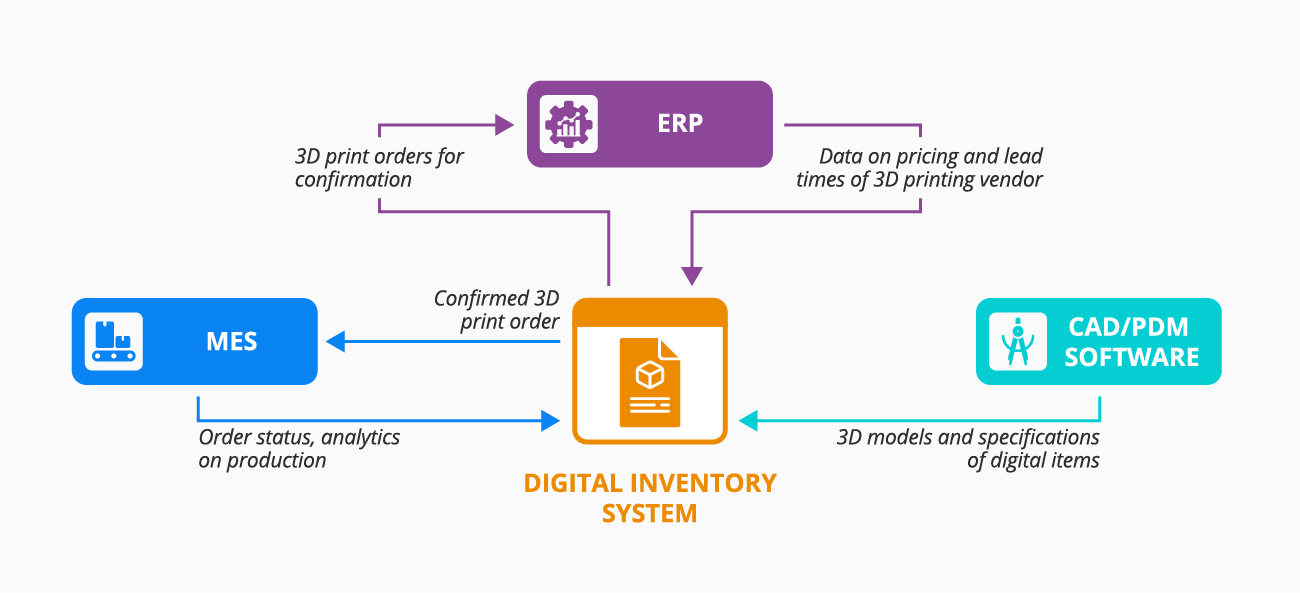

Important Integrations for a Digital Inventory System

The integration of a digital inventory system with other related systems helps automate AM operations and improve their quality (e.g., by automatically transferring verified production requirements to production engineers). ScienceSoft recommends setting up the following integrations:

Digital inventory software + ERP

Automated transfer of 3D print orders from digital inventory software to ERP for order confirmation (both for external orders to 3D printing vendors and internal orders); transfer of data on pricing and lead times of 3D printing vendors from ERP to digital inventory software.

Digital inventory software + MES

MES should have a module for 3D printing workflows.

Automated transfer of confirmed 3D print orders with the production requirements to MES for order execution planning and routing; automated order status tracking and transfer of analytics on digital items production back to digital inventory (e.g., to optimize the technical design in case of failed prints).

Digital inventory software + CAD/PDM software

Direct transfer of 3D models and specifications of digital items to digital inventory software to prepare them for production.

Industry-Specific Use Cases & Benefits of Digital Inventory Software

Automotive industry

With a digital inventory management system, automotive companies can substantially reduce costs on warehousing long-tail parts, e.g., by keeping digital copies of spare parts for vehicles moved out of high-volume production instead of physical ones.

Considering the remote location of oil & gas sites, a digital inventory system for AM production of spare parts onsite (e.g., pump manifolds, rotors, sealing accessories) minimizes shipping and inventory carrying costs and costs of production downtime caused by logistics delays.

Manufacturing industry (tooling)

A digital inventory system allows manufacturing companies to save tooling storage costs and cut associated lead times, as well as streamline serial AM production.

Aerospace industry

A digital inventory system helps aerospace OEMs and MROs cut inventory costs on spare parts that are required to be kept for long periods of time by the industry regulations, as well as leverage more agile and consistent 3D production.

Success Factors of a Digital Inventory System

ScienceSoft’s experts recommend that the following important factors should be covered to maximize payoff from the digital inventory system implementation.

Ease of integration

Custom digital inventory software is complementary to a bigger software ecosystem supporting AM production. Thus, building and maintaining well-defined APIs simplify its integration with other systems (ERP, MES, etc.).

Security

Due to an active flow of confidential digital item data needed for AM production, digital inventory software should have data encryption and user activity monitoring established to assure confidentiality of the company’s know-how and data traceability.

Ease of use

Intuitive interface and clear user guides, so that approved users with no expertise in AM can place 3D print orders, thus facilitating agile production of digital inventory items.

How to Build Digital Inventory Software

Digital inventory software development requires an accurate action plan to ensure smooth project flow and avoid financial risks associated with redesign and recoding of particular solution's components. Below, ScienceSoft shares a sample project plan to provide you with a general idea on how a digital inventory software development process may look.

1

Business needs analysis and eliciting requirements for the digital inventory system.

2

Designing the functionality, architecture, and toolkit for the solution.

3

Project planning: scope, deliverables, team composition, timelines, budget, etc.

4

Digital inventory software development: back-end coding, front-end creation, setting up a database.

5

Quality assurance.

6

Integration with the required corporate and third-party systems.

7

User training.

8

Continuous support and evolution of the digital inventory solution (optional).

For more information on the specifics and duration of each stage, please visit our detailed guide to inventory system creation.

Costs to Develop a Digital Inventory System

Based on ScienceSoft’s experience, developing custom digital inventory software may cost around $100,000–$350,000+, depending on the solution’s functional scope, the complexity and specifics of 3D models, the scope of required integrations, the number of users and their roles, and more.

Want to know the cost of your inventory solution?

When Custom Digital Inventory Software is Your Best Choice

ScienceSoft recommends going for custom development if:

- You need to integrate digital inventory software with legacy internal systems (ERP, MES, etc.).

- You need advanced AI-powered functionality tailored to your business specifics (e.g., automated validation and optimization of 3D models for printing).

- You need a blockchain-based digital inventory system for more secure storage and easily traceable sharing of 3D models and production-related data across multiple manufacturing process stakeholders.

Digital Inventory Software Development with ScienceSoft

ScienceSoft offers digital inventory system consulting and implementation services drawing on 35 years of experience in custom software development and software development for the manufacturing industry.

Digital inventory system consulting

- Analysis of your business needs and AM processes.

- Definition of digital inventory software functionality.

- Digital inventory system architecture design.

- Detailed integrations plan (with ERP, MES, etc.).

- Interactive UI prototype (optional).

- Estimation of implementation costs and timelines, as well as risks and the ways to mitigate them.

Digital inventory system implementation

- Business analysis to elicit functional and non-functional requirements for the digital inventory system.

- Digital inventory system architecture design.

- UX and UI design.

- Digital inventory system front-end and back-end development.

- Integration with other systems (ERP, MES, etc.).

- End-to-end quality assurance.

- Post-implementation support and evolution.

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas, US. We create powerful digital inventory systems to help manufacturing enterprises streamline 3D printing workflows. Being ISO 9001 and ISO 27001-certified, we rely on a mature quality management system and guarantee cooperation with us does not pose any risks to our customers' data security. Our mission is driving project success for our clients no matter what.