Custom Stock Control Software Development

In supply chain IT since 2012, ScienceSoft provides full-cycle consulting and development services to help companies implement reliable and cost-effective stock management software.

The Essence of Stock Control Software

Stock control software, or inventory control software, stores complete stock data and enables the monitoring and analysis of stock levels, costs and value of stock items. It helps easily locate stock items and sends alerts when stock replenishment is required. Custom stock inventory control software is aimed to introduce unique capabilities to help companies from various industries maximize the efficiency of their specific stock counting and monitoring processes.

Benefits of stock control software

- Minimized risk of stock-outs due to simplified stock level monitoring.

- Optimized stock carrying costs due to no overstocking issues.

- Reduced labor costs and streamlined completion of sales orders due to automated stock control routines.

The investments in custom stock inventory control software typically pay off in 5–8 months after the solution implementation.

FAQ about stock control software

Types of stock in stock control software

Usually, stock control software dynamically categorizes stock items in 3 groups (the categorization can be deepened and adjusted to the specific needs of a business):

- On-hand stock – refers to the total quantity of the stored stock.

- Reserved stock – includes ordered stock items that are still in a warehouse.

- Available stock – is the stock that can be ordered, or on-hand minus reserved stock.

Depending on your requirements for stock control software, it can be used for controlling only stock items for sale or all stock types such as:

- Stocks of raw materials and components that will be used to manufacture or assemble products.

- Work in process (WIP) – stocks of yet unfinished products in production.

- Finished goods – stocks of products ready for sale.

- Maintenance, repair and operations (MRO) goods – stocks of inventory supporting the production process (tools, consumables).

- Packaging materials – primary packages that protect finished products; secondary packages with labels; bulk packages for transport.

How stock control software is different from inventory management software

- Stock control software monitors real-time stock data (stock levels, condition, and location of stock items) and streamlines ongoing operations like receiving stock, conducting stock audits, completing sales orders, etc.

- Inventory management software is focused on deeper analytics and strategic planning, using stock and sales data to elicit actionable insights for stock optimization, such as setting up optimal stock levels and forecasting customer and lead time demand.

Stock control software can be used as a standalone application or as a part of inventory management software. If you currently have a limited budget, you may start with the implementation of stock control software and add capabilities for stock optimization and demand forecasting as your business grows.

Implementation of stock control methods

- Calculation of optimal stock levels (e.g., based on the economic order quantity (EOQ) formula) and reorder points (based on the reorder point formula).

How does stock control software help? It enables the setup of reorder points for each stock group and sending automated reorder alerts. For large businesses, the system may also leverage AI-based stock optimization and demand forecasting capabilities. - Strategy for selling stock such as first in, first out (FIFO) to ensure perishable and regulated stock is shipped out in good condition.

How does stock control software help? It offers batch control with expiration date tracking. - Regular stock analysis to timely detect problems with stock control processes and sales tactics and find opportunities to improve them. Such opportunities may include cycle counts to spot stock discrepancies, as well as stock sales analytics.

How does stock control software help? Custom stock software consolidates stock-related data and automatically generates stock reports (stock shortage reports, ABC analysis reports, cycle count reports, etc.).

Advanced technology for stock control: barcode and RFID

Barcode and RFID technology automate stock control operations, such as stock level monitoring, stock items tracking and stock audits.

Barcode scanners:

- Semi-automation (scanner has to be manipulated by a warehouse worker).

- Scanning one barcode at a time.

- High accuracy.

RFID scanners:

- Fully automated scanning.

- Processing multiple RFID tags at a time.

- Better durability.

- Enhanced stock data security due to data encryption.

The choice of stock controlling technology depends on your budget, business needs, and stock specifics (type of stock, layout of sites/warehouses). RFID technology ultimately streamlines stock control and stock handling operations, but its implementation is more expensive and time-consuming. We recommend considering it for organizations with enterprise-scale stock control operations and/or expensive and perishable stock at hand.

Features of a Stock Controlling System

Based on ScienceSoft’s experience with inventory software projects, we have summarized fundamental stock control software features.

Stock database management

- Automated and manual stock data upload.

- Bulk stock data processing (e.g., data import and export from/to integrated systems such as ERP, CRM, and others).

- Stock data versioning, backup, and recovery.

- Role-based stock database access.

- Storage of user activity logs.

Stock item management

- Stock cataloging with filtering and metadata search of stock items.

- Creating and editing stock item summary (containing images, SKU and barcodes, physical characteristics of stock items, such as size and colors, pricing info, etc.).

- Stock bundling and kitting (grouping the same or related items into a single item).

Stock control

- Stock levels monitoring (on-hand stock, reserved and available stock).

- Setup of reorder levels and alerts for low-stock items.

- Restock history (quantity and price of purchased items, dates, locations, suppliers and responsible buyers, etc.).

- Batch control (to track expiration dates for perishable groups of items).

Stock items tracking

- Tracking of stock items status and location.

- Automated tracking with barcode or RFID technology.

Sales order management

- Sales order creation and status tracking.

- Automated invoice generation and approval.

- Automated stock reservation for a sales order.

- Automated packing slips creation.

Purchase order management

- Purchase order creation and approval.

- Purchase order status tracking and history overview.

- Setup of preferred suppliers for particular stock items.

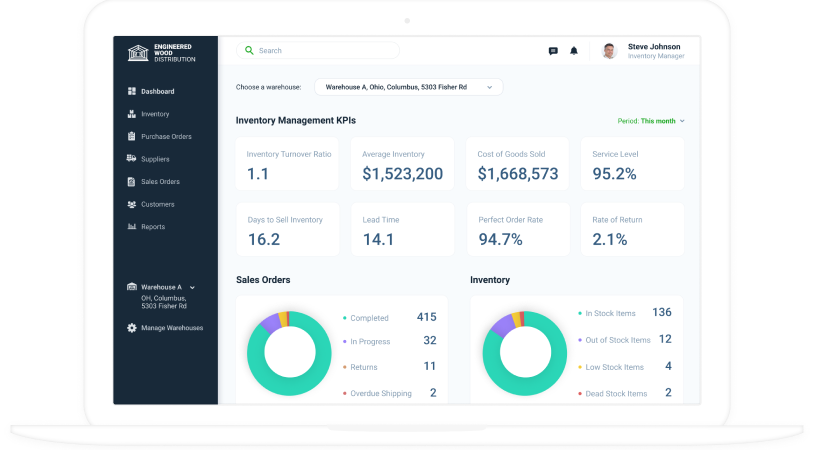

Stock analytics and reporting

- Configurable dashboards.

- Stock audit report (ABC, FSN analysis, etc.).

- Automated customizable reports (cycle counts, shortage alerts, etc.).

- Demand planning (optionally).

Need a Reliable Inventory Control System?

ScienceSoft offers the implementation of a stock control system with functionality tailored to your specific workflows that helps eliminate the issues of stock-outs and overstocks.

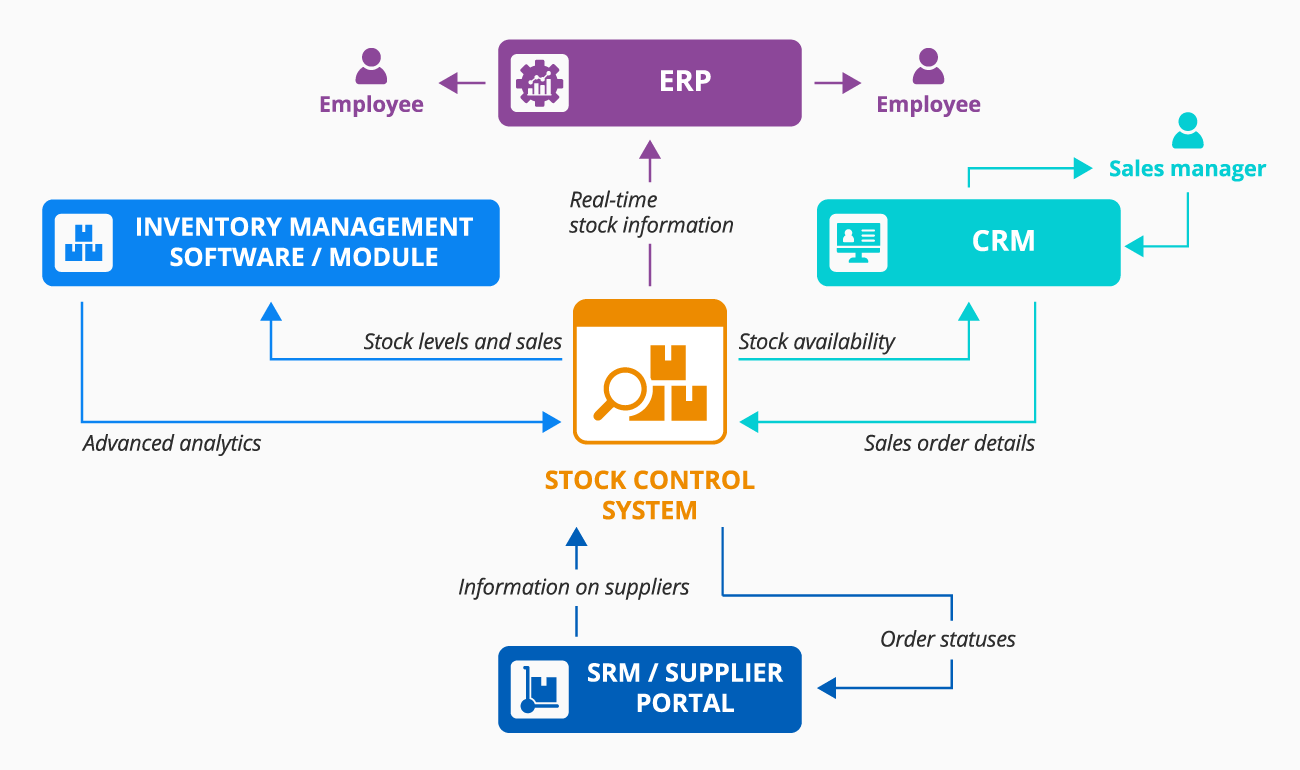

Important Integrations for Stock Control Software

ScienceSoft recommends integrating stock control software with the following back-office solutions to eliminate double data entry across disparate systems and build a resilient supply chain:

- Stock control software + ERP – to provide employees from other business departments with real-time stock information.

- Stock control software + inventory management software/module – to automatically transfer data on stock levels and sales into an inventory management solution and access its advanced analytics features, such as stock optimization and demand forecasting.

- Stock control software + CRM – to keep sales managers updated on stock availability; to automatically transfer sales order details from CRM to stock control software for quicker order completion.

- Stock control software + supplier relationship management (SRM) software/supplier portal – to automatically transfer information on suppliers and their current capacity from SRM software to streamline purchasing in stock control software; to enable tracking of order statuses in both solutions.

Success Factors for the Stock Control System

When designing and building stock control software, ScienceSoft always seeks to cover the following important factors, which help bring the customer additional value across stock control processes.

A high degree of inventory control automation

via automation features and integrations with the relevant systems (ERP, sales, tracking hardware, etc.) to eliminate manual efforts and quickly enforce the necessary inventory operations.

Stock data visibility and analytics

to get a 360-degree overview of real-time and historical stock data, ensure informed inventory planning, and avoid stockouts and overstocking.

Stock Inventory Control Software Development: Success Stories by ScienceSoft

23 results for:

How to Build Stock Inventory Control Software

Stock inventory control software development requires an accurate action plan to ensure consistent project flow and prevent financial and technology risks. Below, ScienceSoft describes key project steps to provide you with a general idea on how your custom stock control software development process may look.

1

Business needs analysis and requirements engineering for the solution.

2

Designing the optimal functionality, architecture, and tech stack for the stock control system.

3

Project planning: deliverables, teams, timelines, budget, etc.

4

Stock control software development.

5

Quality assurance.

6

Stock data migration (from spreadsheets or a previously used inventory control system).

7

Integration with the required corporate and third-party systems, including hardware systems.

8

User training.

9

Continuous support and evolution (optional).

Explore the specifics and duration of each stage in our detailed guide to inventory system creation.

Cost of Stock Control Software

The cost factors for implementing stock control software include:

- The number and complexity of software features (e.g., RFID tracking or AI-based demand planning will increase budget requirements).

- Complexity of integrations with other systems, e.g., integration with legacy solutions (ERP, CRM, etc.).

- Data migration procedures required to transfer stock data from a previously used database (spreadsheets or legacy software).

Based on ScienceSoft's experience, stock control software development for a midsize business may cost around $80,000–$250,000.

Want to know the cost of your inventory control solution?

When Custom Stock Inventory Control Software is Your Best Choice

ScienceSoft recommends custom stock controlling software as a more investment-wise and efficient option than platform-based software when:

|

|

|

Stock Control Software Implementation

ScienceSoft applies 12 years of experience in supply chain software development to implement robust stock control software for operations of any complexity. Our top priority is driving project success for our clients no matter what while keeping within the agreed timeframe and budget.

Stock control software consulting

Our consultants:

- Analyze your business needs for stock control.

- Define an optimal set of stock control software features.

- Help decide between platform-based and custom stock control software.

- Design a secure and scalable architecture for stock control software (for custom software).

- Prepare an integration roadmap (with ERP, CRM, SRM).

- Prepare UX and UI prototypes (optional).

- Estimate implementation costs and time budget, as well as possible ROI.

Stock control software development

Our team:

- Elicits functional and non-functional requirements for stock control software.

- Designs a secure and scalable architecture of stock control software (for custom software).

- Designs UX and UI tailored to your specific stock control workflows (for custom software).

- Develops the front end and the back end of stock control software / sets up and customizes platform-based stock control software.

- Integrates stock control software with other systems (ERP, CRM, SRM, etc.).

- Provides end-to-end quality assurance.

- Provides post-implementation support and software evolution.

About ScienceSoft

ScienceSoft is a global IT consulting and software development company headquartered in McKinney, Texas. We help businesses implement inventory control management systems to avoid stock-outs, optimize stock costs and automate stock control workflows. Being ISO 9001 and ISO 27001-certified, we rely on a mature quality management system and guarantee cooperation with us does not pose any risks to our customers' data security. For more details on our approach, feel free to check our offer on software development services.